ACCURATE

VERSATILE

ADAPTABLE

High resolution sensing of liquid properties

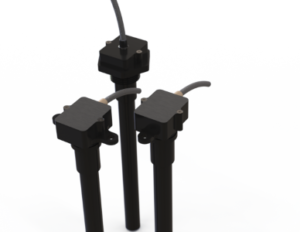

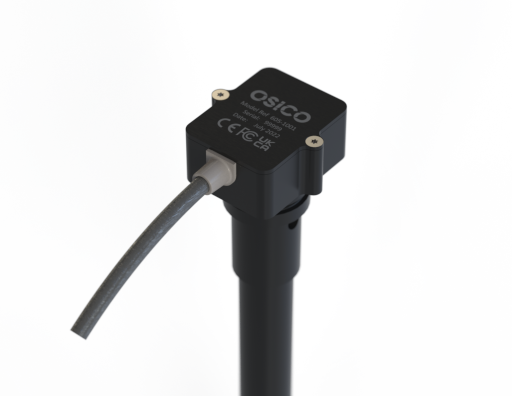

618 - Premium Spec lightweight sensor

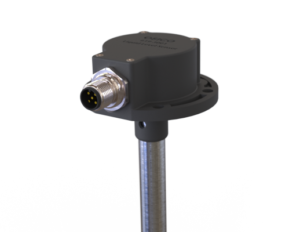

619 - SAE 5 Bolt Mount sensor

HOW DO CAPACITIVE SENSORS WORK?

Understanding Capacitive Liquid Level Sensors

Capacitive liquid level sensors offer a reliable and precise method for monitoring the level of various liquids in tanks, containers, and other vessels. At Osico, we’re committed to helping you understand how these sensors work and how they can benefit your applications.

Principle of Operation

Capacitive liquid level sensors operate based on the principle of capacitance. Capacitance is a measure of the ability of two conductive materials separated by a non-conductive material (dielectric) to store electrical charge. In the context of liquid level sensing, the conductive materials are typically electrodes, and the dielectric material is the liquid being measured.

When a capacitive sensor is placed in contact with a liquid, it forms a capacitor where one electrode is the sensor itself, and the other electrode is the liquid. The capacitance of this capacitor varies depending on the dielectric constant of the liquid and the distance between the electrodes.

Detection Process

As the level of the liquid changes, the dielectric constant between the electrodes also changes, causing a corresponding change in capacitance. This change in capacitance is detected by the sensor electronics and converted into a measurable signal.

Key Components

- Electrodes: The conductive plates that come into contact with the liquid.

- Dielectric Material: The liquid being measured, which acts as the dielectric between the electrodes.

- Sensor Electronics: The circuitry responsible for measuring the capacitance changes and converting them into usable data.

- Output Interface: The interface through which the sensor communicates the liquid level information to a control system or display.

Advantages of Capacitive Liquid Level Sensors

- Accuracy: Capacitive sensors offer high accuracy in liquid level measurement.

- Material Flexibility: One of the key advantages of capacitive liquid level sensors is their versatility in material selection, allowing them to be tailored to specific application needs. We offer capacitive sensors constructed from a range of materials, including Aluminium, Stainless Steel, and Carbon Fibre, each offering unique benefits to suit various requirements.

- Versatility: They can be used with a wide range of liquids, including water, oil, chemicals, and more.

- Reliability: Capacitive sensors are known for their durability and reliability in various operating conditions.

- Compatibility: They can be easily integrated into existing systems and are compatible with different tank materials.

Applications

Capacitive liquid level sensors find applications in various industries, including:

- Industrial processes

- Chemical processing

- Food and beverage

- Pharmaceutical

- Automotive

- Environmental monitoring

Conclusion

At Osico, we offer a range of capacitive liquid level sensors designed to meet the diverse needs of our customers. Whether you need a sensor for a small-scale application or a large industrial system, our team is here to help you find the right solution. Contact us today to learn more about how capacitive liquid level sensors can enhance your operations.

Discover our advanced high-resolution liquid level sensors tailored for Fuel, Oil, Coolant, and Water applications

Explore our durable Rotary and Linear Position sensors designed for Industrial & Off-Highway applications.

Experience IoT connectivity: monitor switches, sensors, and transmit data via GSM

Elevate industrial monitoring with our plant & machinery condition-based sensors.